The following article was featured in Pacific Ports Magazine October/November issue (view the digital version here).

Empty shelves, delayed deliveries, and rising costs have made supply chains front-page news. From cyber-attacks and global conflicts to pandemics and port congestion, disruptions have exposed just how fragile and interconnected our logistics networks really are. The world has learned that when one link breaks, the entire chain feels the impact.

In this high-stakes environment, real-time visibility and rapid response are no longer luxuries; they’re mission-critical. That’s where digital platforms like Port Optimizer™, pioneered by the Port of Los Angeles, are reshaping how ports and stakeholders manage complexity, anticipate disruptions, and keep cargo moving.

From bottlenecks to breakthroughs

Originally launched as a real-time visibility tool, Port Optimizer evolved rapidly during the pandemic. The Port of Los Angeles introduced the Control Tower, a suite of modules designed to help stakeholders navigate the unpredictable supply chain landscape. As import volumes first plummeted and then surged to historic highs, the port used data to pinpoint bottlenecks and take swift, informed action.

A digital backbone for resilience

At its core, Port Optimizer consolidates data from across the supply chain into a single, intelligent platform. This integration enables:

- Faster decision-making

- Proactive communication

- Better alignment of people and resources

By leveraging historical trends, real-time updates, and predictive analytics, the Port of Los Angeles can anticipate volume fluctuations, whether driven by tariffs, pandemics, or geopolitical disruptions.

Tools that drive performance

Control Tower provides high-level metrics and KPIs, including:

- Truck turn times

- Cargo dwell times

- Current and future cargo volumes

- Rail & truck velocity metrics

- Historical views

These insights empower stakeholders to coordinate more effectively and respond to challenges with agility and precision.

The future of port logistics

The success of Port Optimizer highlights a broader truth: the future of supply chains depends on communication, coordination, and collaboration. All powered by data and technology. As global trade continues to evolve, ports that embrace digital transformation will be best positioned to lead. But leadership starts with action. Ports must begin somewhere, based on their current level of digital maturity. Whether it’s implementing basic visibility tools or deploying advanced analytics platforms, taking the first step is critical to building long-term resilience and competitiveness.

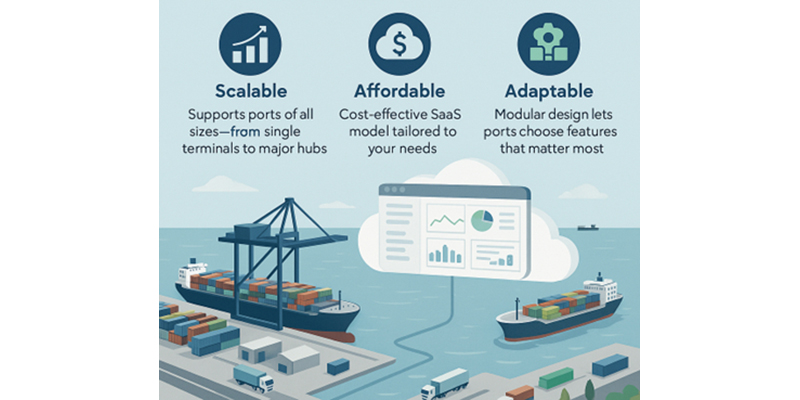

Scalable, affordable, and adaptable

Thanks to its cloud-based, modular design, Port Optimizer can be deployed as a cost-effective SaaS (software as a service) solution for ports of all sizes.

Whether a landlord port with six container terminals or an operating port handling a single general cargo terminal, each port can customize its Control Tower display based on specific needs and priorities. The SaaS fee is determined by the features and content selected, ensuring flexibility and scalability.

Navigating the future with data-driven confidence

In closing, as global supply chains face mounting pressures from unpredictable disruptions, the Port Optimizer stands out as a beacon of innovation and resilience. By transforming fragmented logistics into a unified, intelligent ecosystem, it empowers ports and stakeholders to act swiftly, collaborate effectively, and plan proactively. The Port of Los Angeles has demonstrated that digital transformation is not just a technological upgrade, it’s a strategic imperative. With scalable, cloud-based solutions tailored to diverse operational needs, Port Optimizer is paving the way for a smarter, more agile future in global trade. Ports that embrace this evolution will not only survive the next disruption; they’ll thrive in it.

For more information on Port Optimizer, visit:

https://www.wabteccorp.com/digital-intelligence/transportation-management/port-optimizer